How To Store and Use Flammable Liquids – Part 2

In our first segment, we reviewed the technical/behavioral nature of flammable liquids, key considerations to control the hazards, and the primary best practice standards that govern their use and storage. In a related post, Fire Hazards of Spray Finishing with Flammable Liquids, we also discussed the hazards of spray finishing and the proper ways to control exposure to these hazards.

Storage Containers

Standards

Storage containers can vary in type and size, but it is important to recognize that the National Fire Protection Association (NFPA) sets standards on the use and storage of flammable liquids, but does NOT approve individual designs or specifications of containers. This is the responsibility/role of the U.S. Department of Transportation (DOT).

The DOT publishes this information in their standard titled Title 49, Code of Federal Regulations, Parts 100–199, or by Part 6 of the UN Recommendations on the Transport of Dangerous Goods. NFPA does recognize other organizations/standards that set standards and perform tests on containers. These include the following for metal or plastic containers:

- ASTM F 852, Standard Specification for Portable Gasoline Containers for Consumer Use

- ASTM F 976, Standard Specification for Portable Kerosene and Diesel Containers for Consumer Use

- ANSI/UL 1313, Standard for Nonmetallic Safety Cans for Petroleum Products

- ANSI/UL 30, Standard for Metal Safety Cans

- ANSI/UL 1314, Standard for Special Purpose Metal Containers

- FM Global Approval Standard for Safety Containers and Filling, Supply, and Disposal Containers — Class Number 6051 and 6052

The NFPA also recognizes National Motor Freight Classification (NMFC), or Rule 51 of the Uniform Freight Classification (UFC), for Types 2A, 3A, 3B-H, 3B-L, or 4A for fiber drums containers. NFPA 30, Chapter 9 has further details on these standards.

Venting

Vents are installed in the top of portable tanks and intermediate bulk containers to prevent the discharge of liquid under overpressure situations by expelling vapors generated by an increase in temperature. According to NFPA 30, each portable tank or intermediate bulk container shall be provided with one or more devices installed in the top with sufficient emergency venting capacity to limit internal pressure under fire exposure conditions to a gauge pressure of 10 psi (70 kPa) or 30 percent of the bursting pressure of the portable tank, whichever is greater.

Size

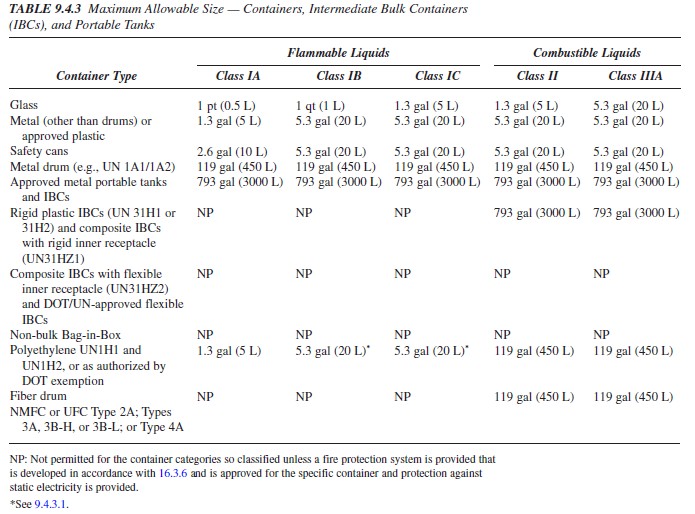

Table 9.4.3 of NFPA 30, Ch. 9 sets the allowable size of containers:

Note in the table that plastic containers are not NOT ALLOWED to be used with flammable liquids (‘NP’= not permitted), unless the liquids are water miscible. We also covered this in our first post on flammable liquid and storage.

Storage Options

There are three primary storage options available with flammable liquids:

- In portable storage cabinets

- In a storage room

- Outside the building (either in the open, an attached or detached building, or storage locker)

During operations when flammable liquids need to be used, a small supply can be located outside of “approved” storage in one fire area per OSHA 1910.106.

However, it is a best practice to have all flammable liquids stored with one of these methods whenever possible. Note that safety cans (UL/FM approved) with appropriate dispensing equipment should always be used for dispensing from portable containers.

Outside the Building

Often the easiest and least expensive options are to store flammable (and combustible) liquids outside the building. Outside storage of course provides natural ventilation; however, there are climate (i.e. temperature) and security concerns. This of course depends on whether the flammable liquid can be stored safely outside.

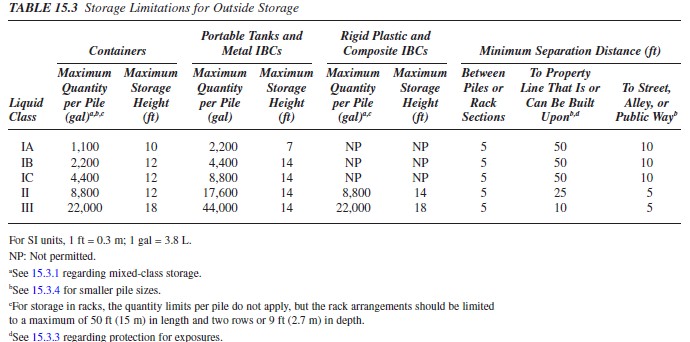

The material safety data sheets and other information from the manufacturer should be consulted before this is done. Once it has been determined that it is safe to do so, NFPA publishes the following chart with regard to distances, quantities, etc.:

Additional controls include the following:

- The area should slope away from the building or be diked in the event of a spill so that the liquid does not flow toward the building.

- The storage should be secured (e.g. fenced)

- It needs to be stored in such a way that fire apparatus can have easy access to it.

- The distances between the outdoor storage and an occupied building will vary depending on several factors- the fire wall barrier rating (construction of the wall); fire protection of the building and other factors.

Storage Cabinets

An efficient and cost effective means to portable storage may be storage cabinets. Cabinets are not without hazards, which include:

- Risk of spills

- Possible tip-over or blockage of egress

- Maintenance of vent and grounding integrity

- Condition of floor surfaces under the cabinet that may make the cabinets unstable

Not any “ordinary” cabinet can be used, however. NFPA 30, 9.5.3 specifies that the cabinets must meet one of four sets of specifications:

- Storage cabinets designed and constructed to limit the internal temperature at the center of the cabinet and 1 in. (25 mm) from the top of the cabinet to not more than 325°F (163°C), when subjected to a 10-minute fire test that simulates the fire exposure of the standard time/temperature curve.

- Metal storage cabinets constructed in the following manner shall be acceptable:

- The bottom, top, door, and sides of the cabinet shall be at least No. 18 gauge sheet steel and shall be double-walled, with 11/2 in. (38 mm) air space.

- Joints shall be riveted, welded, or made tight by some equally effective means.

- The door shall be provided with a three-point latch arrangement, and the door sill shall be raised at least 2 in. (50 mm) above the bottom of the cabinet to retain spilled liquid within the cabinet.

- Wooden cabinets constructed in the following manner shall be acceptable:

- The bottom, sides, and top shall be constructed of exterior grade plywood that is at least 1 in. (25 mm) thick and of a type that will not break down or delaminate under fire conditions.

- All joints shall be rabbetted and shall be fastened in two directions with wood screws.

- Where more than one door is used, there shall be a rabbetted overlap of not less than 1 in. (25 mm).

- Doors shall be equipped with a means of latching, and hinges shall be constructed and mounted in such a manner as to not lose their holding capacity when subjected to fire exposure. (e) A raised sill or pan capable of containing a 2 in. (50 mm) depth of liquid shall be provided at the bottom of the cabinet to retain spilled liquid within the cabinet.

- Listed cabinets (e.g. Underwriters Laboratories) are acceptable, provided they meet the provisions of section #1.

If fire cabinets are used for flammable liquids storage, the storage must meet the following requirements:

- Less than 120 gal (454 L) of Class I, Class II, and Class IIIA liquids shall be stored in a storage cabinet. Of this 120-gal total, not more than 60 gal (227 L) shall be Class I and Class II liquids.

- Not more than six storage cabinets shall be located in any one fire area. (three for non-sprinklered buildings).

- Storage cabinets shall be marked in conspicuous lettering: "FLAMMABLE — KEEP FIRE AWAY."

- If the volume of storage is more than the above guidelines, than an approved flammable storage room should be constructed.

One question that often arises is whether cabinets need to be vented. Per NFPA 30, the simple answer is no. The Apex in 9.5.4 explains that venting of storage cabinets has not been demonstrated to be necessary for fire protection purposes, and could compromise the ability of the cabinet to adequately protect its contents against fire because cabinets are not generally tested with any venting.

However, it is recognized that some jurisdictions might require storage cabinets to be vented and that venting can also be desirable for other reasons, such as health and safety. In such cases, means of accomplishing this can include thermally actuated dampers on the vent openings or sufficiently insulating the vent piping system to prevent the internal temperature of the cabinet from rising above that specified.

The details of the requirements for this type of storage can be found in NFPA 30, Chapter 9 (beginning with 9.5). There are additional special occupancy requirements that must be considered.

Flammable Liquid Storage Room

When the above two options do not work, an approved liquid storage room may be an option. The quantities allowed will depend on the nature of the occupancy, whether the room is an inside storage room, cutoff room, or attached building, and the local authority having jurisdiction (AHJ).

The primary requirements (in a very concise format) for an inside storage room are as follows:

- Interior walls and ceiling should have a 3 hr. fire resistance. The exterior wall should have accessibility for fire-fighting operations through windows, access panel, or lightweight noncombustible wall panels.

- Explosion venting capability through lightweight wall assemblies or through windows designed for this purpose (NFPA 68 Guide for Explosion Venting has additional information.

- All openings in interior walls should be protected by automatic 3-hour rated fire doors.

- For containment (to prevent fuel spread), liquid-tight curbs should be provided and ramps at least 6” in height (or higher if the amount of liquids would fill the room to a higher level than this) across the width of the opening. An open-grilled trench on the inside face which drains to a safe location is also an option.

- Wall scuppers, trapped floor drains, or trapped trench drains terminating in a safe location. The drains should be sized to effectively handle the expected sprinkler discharge.

- Electrical wiring and equipment suitable for Class I Division 2 locations, except within three feet of a flammable dispensing nozzle area where it should be suitable for Class I, Division I.

- Grounding and bonding facilities for containers at any dispensing location for Class I liquids.

- Mechanical ventilation of 1CFM/ft2 of floor area but not less than 150CFM. Fan(s) should have blades of non-sparking material with exhaust pickup(s) taken within 6 in. of the floor.

- The room should be equipped with an approved fire suppression system (approved by the Authority Having Jurisdiction, or “AHJ”) or fire sprinklers in accordance with Chapter 16 of NFPA 30 (depending on the storage array inside the room). Generally, rooms with containers more than 5 gallons will require sprinkler system densities of 0.25/3,000 gpm/ft2 or greater (depending on variables such as storage array, height and sprinkler temperature).

- Room heat provided by indirect means or by equipment listed for such applications.

Detached Buildings & Hazardous Materials Lockers

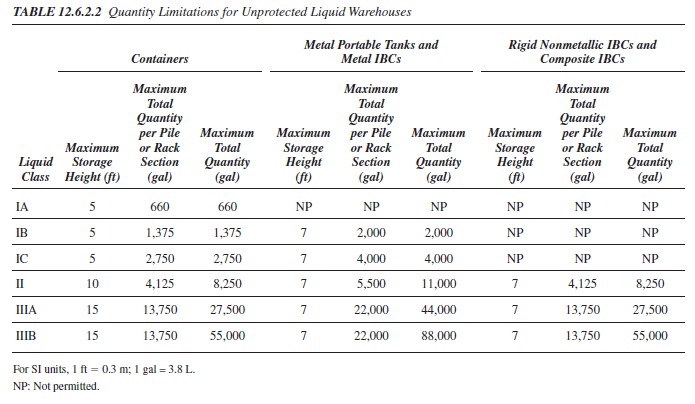

In Chapters 13 and 14 of NFPA 30, there are two other options related to the liquid storage room. There is no limit to the total quantity of liquids stored in a liquid warehouse, however, the storage heights and maximum quantity per pile or rack section for unprotected storage must be in accordance with the following table:

The distances from an unprotected warehouse should be 200’ or can be reduced to 100’ if the AHJ determines that definition of “protection for exposures” exists (the concept of “protection for exposures” is one of the more “subjective” concepts of NFPA 30 and includes such considerations as the fire department response, human element response, or other barriers such as a water curtain are taken into account by the AHJ).

With regard to Hazardous Materials Lockers, these are movable prefabricated structures of no greater than 1,500 ft2. These can be as close as 20’ to an occupied building on the property, but there are several considerations that are detailed in Chapter 14 that must be considered. They should be UL listed or Factory Mutual (FM) approved as an HML.

Conclusion

As can be seen, there are several options for controlling the risk associated with the storage of flammable liquids. Our primary “go-to” standard is NFPA 30 Flammable and Combustible Liquids Code, and the most recent edition is the 2012 edition. The 2008 edition had the most changes from a previous edition (2002) in a while from a historical standpoint, however, it is always “best practice” to work with the latest standards (even though many AHJ’s typically are one or two editions behind from a regulatory standpoint).

From a workplace safety standpoint (geared toward protecting employees and occupants of buildings), the Occupational Health & Safety Administration (OSHA) standards are enforceable by law, and although most of their standards are derived from NFPA standards (from a fire protection/mitigation and life-safety standpoint), there are some differences- especially with regard to the handling of flammable and combustible liquids (as opposed to storage, which is dealt with here).